[PR] MG Tech Moove – intelligent handling solutions

MG Tech offers transitic solutions to help operators in all industrial sectors (agri-food, pharmaceuticals, cosmetics, logistics, etc.) in their handling operations.

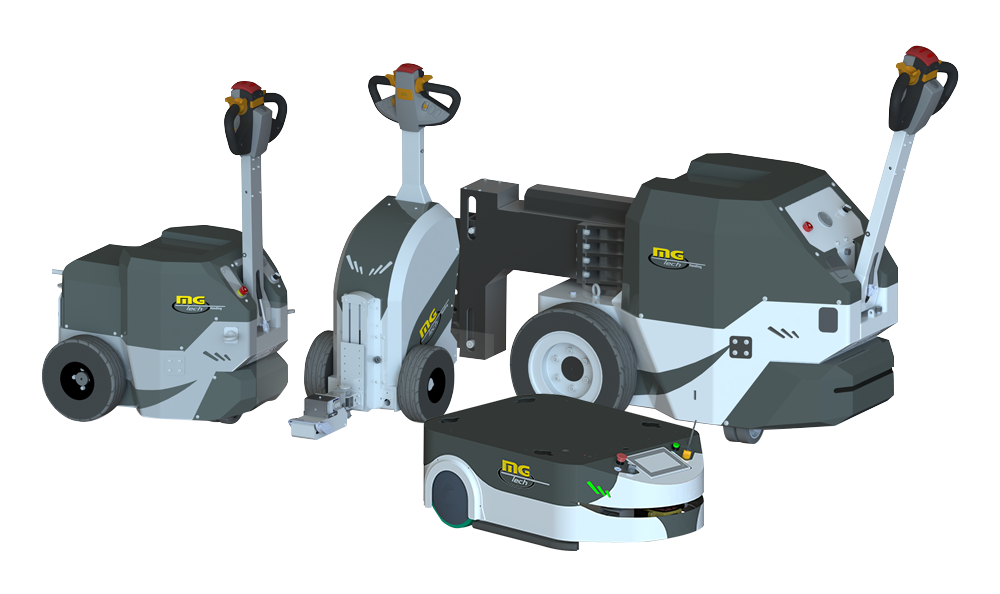

Among these solutions, the MG Tech range includes:

- Pusher tractors to handle heavy loads up to 15 tons, easily and without CACES certification.

- Robotic handling solutions with AGV / AIV robots for lifting, towing and moving heavy loads.

Pusher tractors, the end of efforts to move heavy rolling loads

Compact and handy, the 100% electric Optimover pusher tractors make movements safer and allow the pushing and towing of heavy rolling loads of 1,000 to 15,000 kgs. Used without CACES, this handling equipment provides operators with greater comfort, ergonomics and optimum safety.

"This equipment considerably reduces the risk of MSDs, such as back pain, shoulder pain or wrist pain, ailments that affect a large number of companies and industries" explains Eric Gautier, CEO of the MG Tech group.

Different options and tools are available depending on the use of the equipment and the rolling loads to be handled (hitching by pin or clamp, wheels with non-marking tires, low or high shovel, etc.)

Three sizes are available in the Optimover MG Tech range:

- Optimover S / S +: up to 1.5 tons

- Optimover M: 3 tons

- Optimover L: from 6 to 15 tons.

Robotic solutions to facilitate the movements of operators

"In the context of the development of Industry 4.0, robots are transforming the activities of tomorrow. The automation of load movements makes it possible to support operators in increasing their skills in their missions and to train them for the professions of tomorrow. These robots perform the various painful and / or repetitive tasks, give operators a better quality of life and better availability for operations with more added value” continues CEO MG Tech.

MG Tech AGV / AIV robots are collaborative mobile equipment, modular and easy to use. They are ideal for line procurement, finished product recovery or order picking.

The AGV (Automated Guided Vehicle) version moves along predefined lines with electromagnetic tracking TAGs, while the AIV (Automated Intelligent Vehicle) version advances thanks to navigation technology with mapping and recognition of the environment in which it is located.

Compact and robust, MG Tech collaborative robots can be enhanced with options and additional accessories to fulfill lifting or conveying functions.

Two models exist in the MG Tech range:

- The Minibot: up to 100 kgs carried and pulled

- The Evobot: up to 800 kg in carried and 3 tons in traction

MG Tech presentation

Specialist in industrial robotics for end-of-line packaging solutions for activities in agri-food, pharma-cosmetics and industrial sectors ... the group has diversified into mobile robotics with the manufacture of AIV-AGV and push tractors.

Labeled "Industry of the Future Showcases", the MG Tech group has made interconnectivity a pillar of its strategy. Day after day, the MG Tech group is committed to supporting its industrial customers over the long term with reliable and upgradeable equipment that offers greater productivity, agility and comfort.

Press contact

communication@mg-tech.fr

+33 (0)2.41.73.15.48