Key figures

Number of cases

Speed/robot

Footprint

Machine features

- Storage type: flat or upright

- Case types: 4 corners glued cases, shelf-ready trays, trays with ledge, stackable cases

- Product types: pots, pack, case, tri-fold boxes, bottle, thermoformed/sealed/filmed trays, sachet, flowpack/doypack, blisters…

-

Technical features & benefits

Easy and quick format changeovers

Our top load case packers are perfectly adapted for a wide range of products and cases. Format changeovers can be carried out without any tools. Guidance and video tutorial are available on the HMI screen to help operators for this operation.

Ergonomic machine

As all our end of line packaging machines, our top load case packer is designed to be ergonomic and to bring comfort and safety to operators. It is equipped with an intuitive 12’’ HMI screen, in which we can access all production and machine parameters, full height doors to ease maintenance operations, colored LED inside the machine to visualize the state of different areas and identity rapidly the default areas.

Customized and modular design

Our top load case packers can be totally adapted and customized according to your production rates, types of products, types of cases, storage… Machines can be connected with upstream and downstream existing equipment. Our engineering team is attentive to your projects and will always propose you the best design that will meet your needs and constraints.

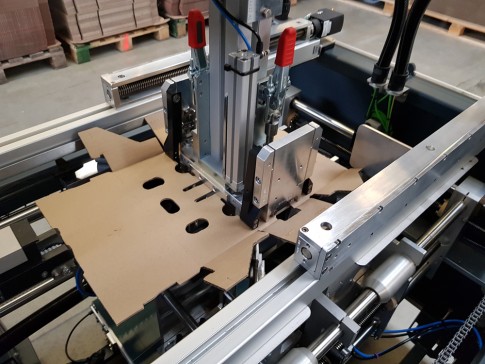

Integration of robots for packing

Our top load case packers are designed with different types of robots (Gantry, Delta from 2 to 5 axes, poly-articulated) according to the products to pack and the final case.

Set up to perform “Pick and Place” operations, each robot is equipped with interchangeable tools capable of performing numerous movements: translation, rotation, tilt, etc. It makes our top load case packer evolutive and modular.

In addition of packing operation, our robots are able to group products or batch them upstream.

-

Additional packing functions to complete the end of packaging line

The Top load packing operation can be supplemented with other features specific to your needs, thus MG Tech provides you a complete and automated packaging line: